RotoMatic R90

RotoMatic - Redevelopment

6400211

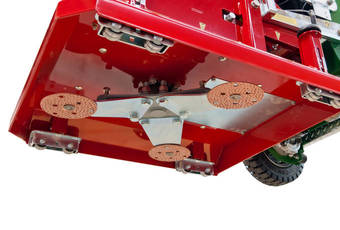

Grinding machine for synthetic sports surfaces.

Removal depth max. 2 mm, working width 900 mm.

The RotoMatic R90 belongs to the second generation of the SMG grinders. It is generally used to grind up synthetic sports surfaces, especially structural coatings and prefabricated structural coverings of surfaces needing renovation.

With a working width of 900 mm and the drive power output that increased by 26 kW (35,3 HP), the area performance of up to 160 m²/h can be achieved. With the use of 16 ball bearing rollers, the grinding unit scans the surface to be ground. The working depth is precisely adjusted by 4 adjustment spindles.

The operator's station offers clear view of the grinding surface and the ergonomically arranged controls.

Electro hydraulically adjustable feed speed control guarantees optimum results. The direct steering feature provides exact directional movements and stability.

An additional driver's seat can be added (left or right), in cases when the machine has to be operated for long periods of time. The three carbide grinding discs can be set and locked in three different positions. This allows the discs to wear uniformly and prolongs their working life.

Technical information:

| Drive | petrol engine 26 kW (35,3 PS)

|

|---|---|

| Working width | 900 mm |

| Area performance | 160 m²/h, dependent of type of surface and grinding removal and ambient air temperature |

| Material removal (grinding depth) | 1 - 2 mm in a single operation |

| Weight | 650 kg |

| Dimensions | L 2,000 x W 900 x H 1,250 mm |

| Shipping dimensions | L 2,150 x W 1,065 x H 1,400 mm |

Subject to technical changes